Recipe for choosing appropriate materials to build industrial factories

Do you have the intention of building a brand new factory? Are you wondering how to commence buying materials that are both economical and effective? If you have these concerns, let's find out together with BMB Steel for answers in the article below!

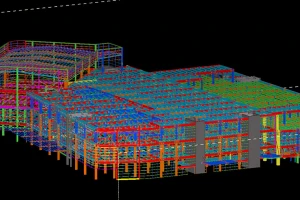

1. Steel structure - Steel truss frame

In fact, in factory construction, the tube steel truss frame is more durable and more economical than the black steel truss frame or the wooden truss frame. Its advantages are as follows:

Light-weight

The weight of the tube steel truss frame is 5 times lighter than the black steel truss frame. Regardless of its lightweight nature, this material is tremendously durable with highly appreciated linkage ability. Besides, it saves manpower to transport since the weight of the steel truss is relatively light.

High economic efficiency

Along with its lightweight nature, the tube steel also has high economic efficiency as it saves money on foundation beams. Simply, that the weight of the tube steel truss is low makes the roof light. Besides, the wall will not have to bear a strong impact force like the black steel truss. Thus, the factory owner will not need to pour concrete underground to reinforce the wall frame anymore.

High aesthetic

Each steel truss frame on the market is covered with a zinc coating. This coating keeps the zinc color stable over time as well as resists rusting irrespective of the severe impacts of the weather conditions. This feature is something that the black steel truss frame does not have.

Additionally, the zinc coating is exceedingly anti-termite, which is a disadvantage of the common wooden trusses.

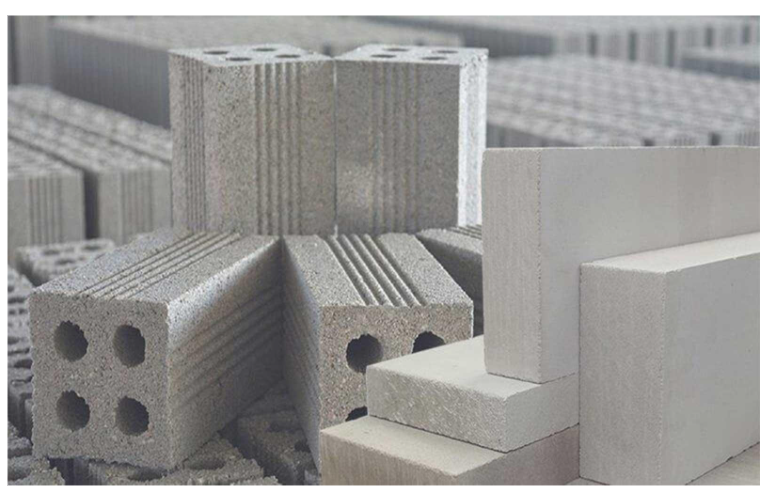

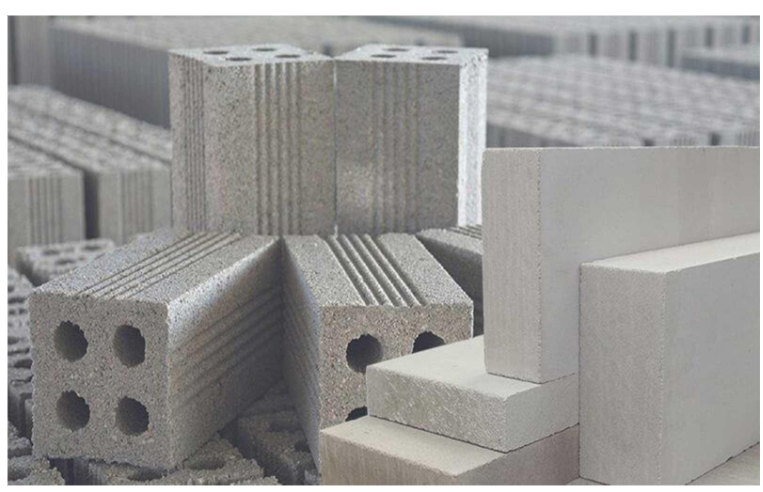

2. Fireproof materials - Unburnt building materials for factories

Currently, the current situation of global warming is becoming serious, people have a tendency of using fireproof building materials for industrial factories. Consequently, more investment owners and contractors tend to choose unburnt building materials for factories.

Here are some reasons why you should choose this type of material:

Material-saving

To produce one billion standard baked bricks, 1.5 million m3 of clay is used. Thus, to produce only one billion bricks, you have spent about 75 hectares of clay equivalent to agricultural land. Rather than using baked brick, we can use adobe brick to solve this problem.

This kind of brick is produced from ash and slag from thermal power plants, metallurgy, and rock dust in the mining industry. Besides, the primary material of this brick is the redundancy of the mining industry; thus, it completely solves the problem of environmental pollution.

Environmental protection

In addition to consuming a huge amount of clay to produce baked bricks, this process also releases nearly 1 million tons of CO2. This is not a small number! For the next generation of children, from now on, we should pay attention to environmental issues from choosing materials to build factories.

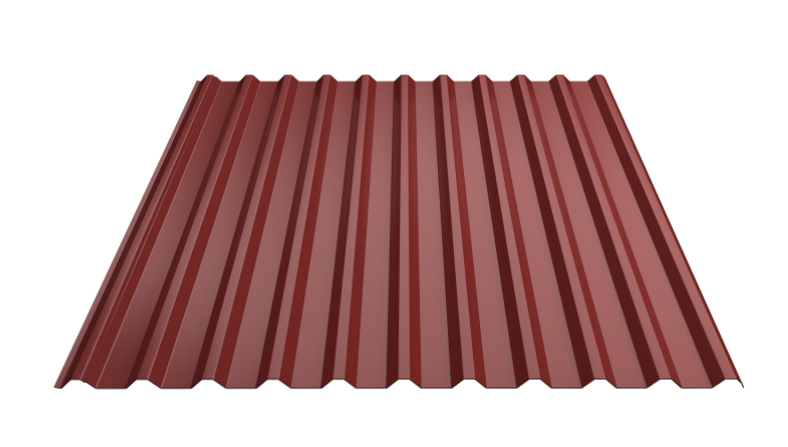

3. Roofing materials for factories

There are two most popular roofing materials for factories:

6 square wave corrugated iron

The 6 square wave corrugated iron is characterized by its high angled wave’s trough. The wave troughs create stability and drainage ability, avoiding water stagnation. This type of corrugated iron is also resistant to dents and deformations by virtue of its stiffness-reinforced wave troughs.

Thanks to the above advantages, 6 square waves corrugated iron is a preferred choice in small and medium industrial factories.

11 square wave corrugated iron

The 11 square wave corrugated iron has all the advantages of the 6 square wave corrugated iron. However, the resistance of the 11 square wave corrugated iron is two times better than the 6 square wave corrugated iron. Obviously, the extremely fast drainage of 11 square wave corrugated iron is also much better than 6 square waves corrugated iron.

With the above advantages, 11 square wave corrugated iron is a good choice in large-scale industrial factories.

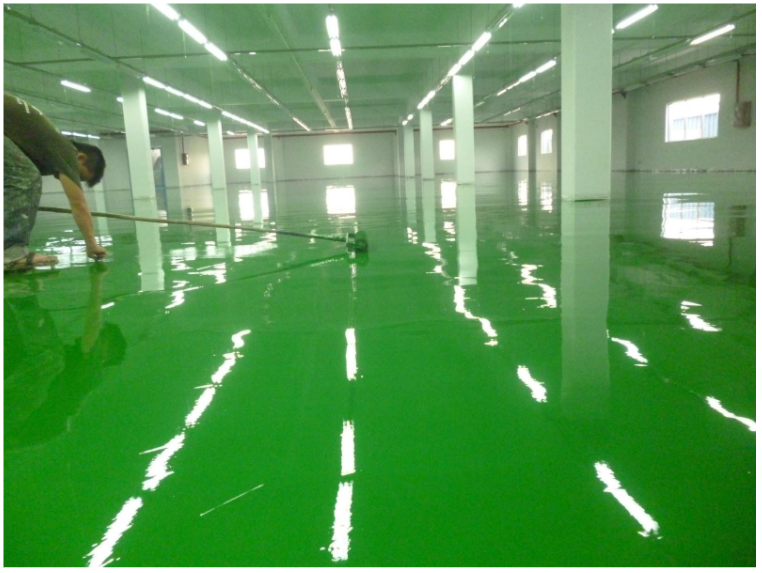

4. Epoxy paint

The epoxy paint’s ingredients include the curing agent part and the coating part. They are two key factors to create a durable epoxy paint with high load capacity, anti-slip, anti-dirt and easy-cleaning ability.

Epoxy paint is a common paint used to paint floors to gloss and balance the surface. Thus, epoxy paint has a high anti-stick layer, which makes it easy to clean and gain the highest aesthetic requirements.

Floors with epoxy paint will be highly waterproof for factories with floors that are often exposed to water by virtue of specific production problems.

5. Linkage materials

Irrespective of its solidity and durability, steel trusses often lack the connection(“a connection”) with each other. Below, we will introduce to you the two most popular types of steel truss connecting materials.

Bolt: used in connecting purlins with rafter

As an accessory that is responsible for linking columns and roof trusses together, the bolt is a popular and well-known bonding material. With a strength of 8.8, bolts can withstand heavy loads.

Normally, people will use S10T bolts. In case it is necessary to link purlins with steel trusses, M12 bolts will be preferred.

Sika: used in steel-concrete bonding

Most of the roof designs for industrial factories use steel truss frames with concrete roofs. Thus, Sika is a particularly essential material for this bonding.

By virtue of the perfect combination of epoxy resin and special high-strength sealant, Sika is renowned for its impeccable solvent-free adhesion. Thus, they have the ability to bond steel purlins to concrete tightly.

Sika - new generation waterproofing compound

Conclusion

The above article has given factory owners a specifical overview about "Choosing construction materials for industrial factories". Hopefully, through this article, factory owners have been able to make the right choice of investment materials for their own factory projects.